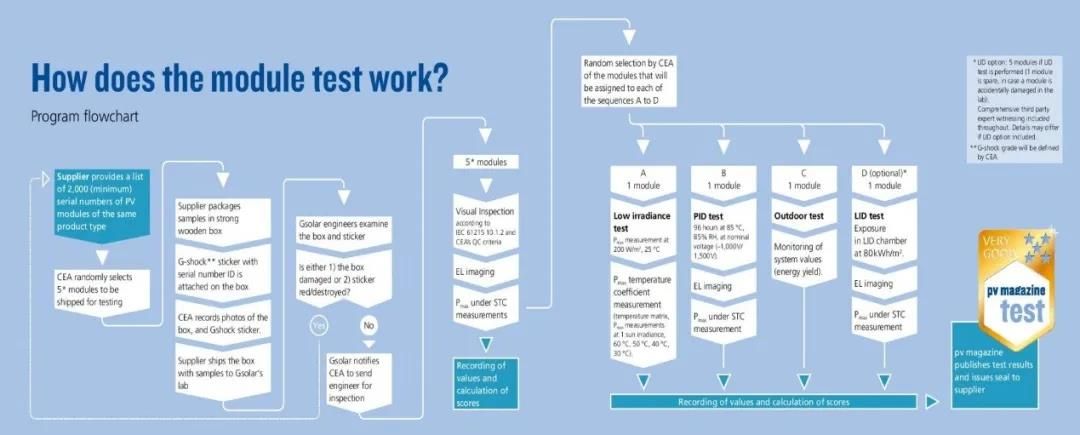

The German-based PV Magazine Group, in

cooperation with CEA in the United States and GSolar in China, has published

the latest results of its energy yield test and LONGi modules were ranked top

in the outdoor category.

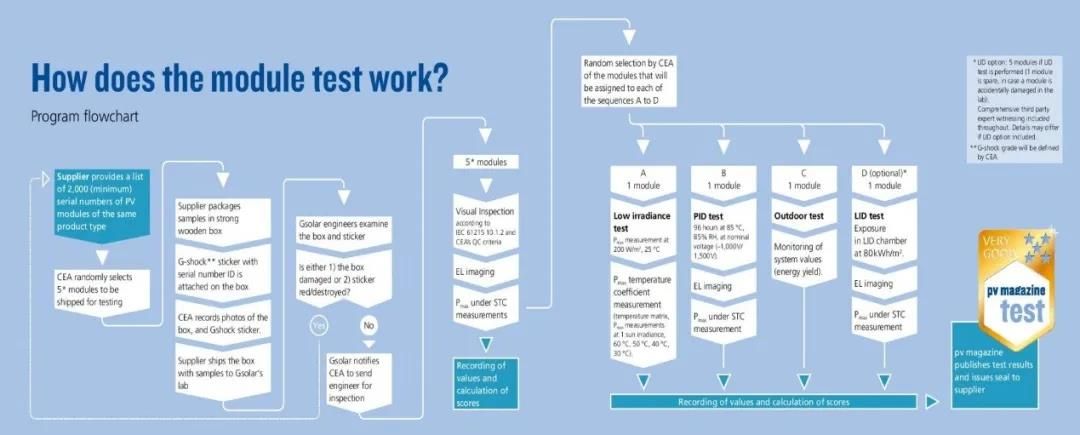

PV Magazine randomly selected test

modules from 2000 mass-produced modules to participate in outdoor testing. Modules

were connected to a string inverter and a Huawei module-level power optimizer

for energy yield monitoring.

Through the above procedure, various uncertainties

of general empirical power plants were eliminated, and the energy yield

capacity of the modules was accurately reflected to provide a reference for global

investors in power plants.

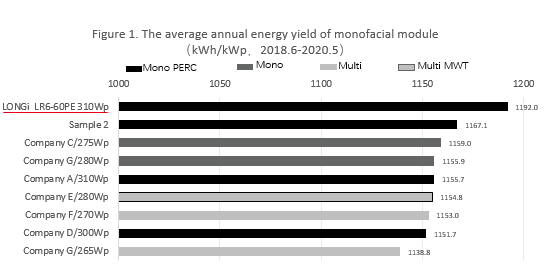

The PV Magazine Module Test provides a

unified test platform for various photovoltaic manufacturers and module types. So

far, the test has gathered data on a variety of modules, including

conventional monocrystalline and polycrystalline, monocrystalline PERC monofacial, bifacial and N-type bifacial modules. From June 2018 to May 2020, LONGi's monofacial,

bifacial and bifacial half-cell PERC modules were tested successively and demonstrated

excellent energy yield capabilities.

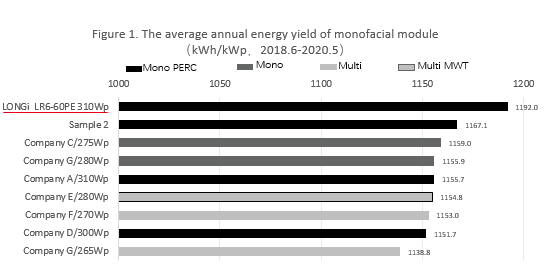

LONGi's monofacial PERC module (LR6-60PE) was the

first to be tested. With the continual addition of new modules for testing over

the past two years, the specific energy yield of this module remained top among

all monofacial modules tested. The average annual energy yield results (2018.06-2020.05)

of the nine monofacial modules that took part in testing are shown in Figure 1.

The yield of LONGi's monofacial PERC module (LR6-60PE) was 1192kWh/kWp (the outdoor

test field located in Xi'an), 3.4% higher than that of the polycrystalline

module of Company F and 2.1% higher than that of the PERC module Sample 2

purchased by PV Magazine on the market. In addition, it can be seen that the

energy yield performance of monocrystalline PERC modules from different

manufacturers is very different, some PERC modules having a lower energy yield

than polycrystalline equivalents.

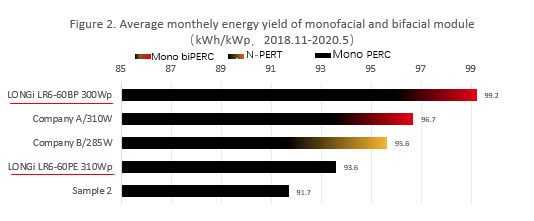

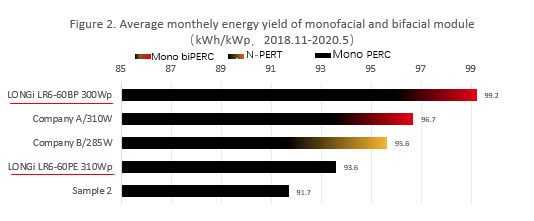

LONGi’s bifacial PERC module (LR6-60BP) joined the

energy yield test in November 2018, and its energy yield also ranked first in

the bifacial module category, 2.6% higher than the bifacial PERC module of

Company A and 3.8% higher than the N-type bifacial PERT module. Compared with the

monofacial PERC module, LONGi’s bifacial PERC module exhibited a significant

backside energy yield gain (the ground surface was replaced with gravel from

artificial turf in September 2019).

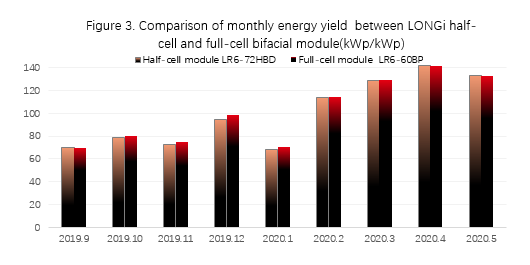

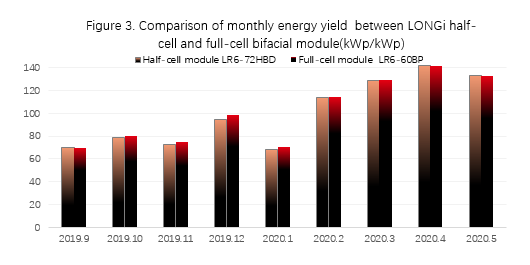

With the full adoption of half-cell technology in

LONGi's module production, its bifacial half-cell PERC module (LR6-72HBD) also

joined the testing in September 2019. According to previous research results from

LONGi and the China Electrical Institute (CEI) in a whitepaper (“Empirical

data from the China Electric Institute (CEI) verifies the power generation

performance of LONGi’s bifacial half-cell module at its pilot project in

Qionghai, Hainan”), the energy yield of a half-cell

module is slightly better when irradiation is higher, and the energy yield of a

full-cell module slightly better when irradiation is lower. The PV

Magazine Module Test also produced similar results to those shown in

Figure 3, the energy yield of the half-cell module being relatively high in the

irradiated month.

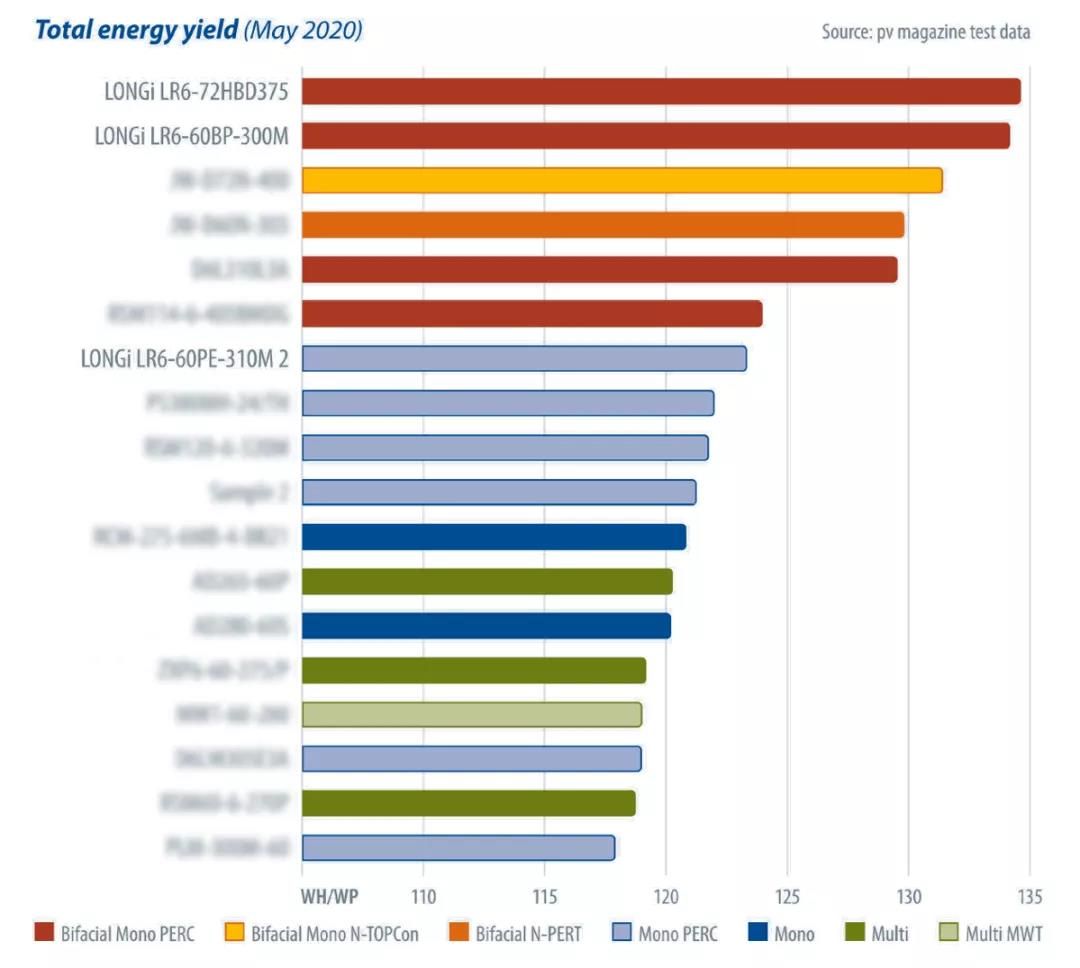

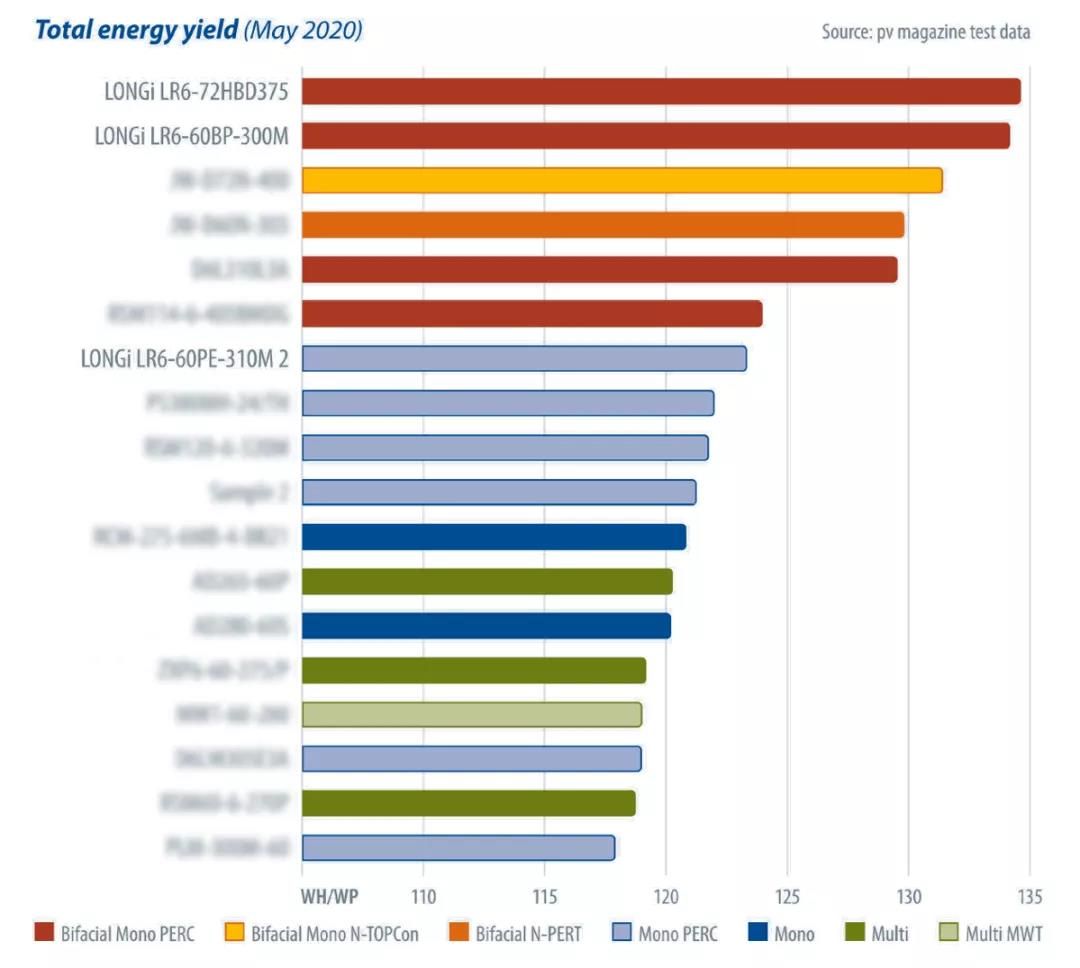

The monthly energy yield data for May 2020 is

shown in Figure 4. Three types of LONGi modules display obvious advantages in energy

yield compared to similar equivalents, its PERC bifacial module being even

higher than the N-type TOPCon module that participated in the test.

The two-year test data has fully verified the

technology leadership of LONGi's previous generations of module products in terms of energy yield capability. LONGi has always

focused on customer value in product development, and new photovoltaic modules

have achieved comprehensive optimization in three aspects: system cost, energy

yield capacity and reliability. Based on the concept of finding the most suitable

module size, LONGi recently launched its new Hi-MO 5 module- an ultra-high power module designed for utility-scale power

plants application - with

front-side power up to 540W and efficiency exceeding 21%. The Hi-MO 5 module maintains

the consistently excellent energy yield performance of LONGi’s product

portfolio. LONGi also adopts “Smart Soldering” technology on

Hi-MO 5, which maximizes light capture and incorporates reliably connected

cells with reduced gap. Due to compatibility with existing manufacturing lines and

plant design systems, LONGi’s Hi-MO 5 can deliver true value to customers in

terms of system cost savings, and provide the best LCOE solution for

ultra-large power plants.